History of QSIL Metals Hermsdorf GmbH

The Hermsdorf plant dates back to 1961. Originally known as Hermsdorfer Pulvermetallurgie, the plant succeeded in developing important refractory metals and technical ceramic products based on novel manufacturing processes. Among the earliest successes were affordable slip rings and contact materials based on silver and tungsten copper alloys (WCu). In 1963, the Hermsdorf plant built its own electron beam furnace to improve heavy metal production capabilities and within two years exploited new patents for refractory metal powders to produce molybdenum and tungsten-based parts, including high-performance tungsten sheet. Electron beam melting (EBM) and powder metallurgy have remained core competencies of Hermsdorf for decades.

Through the constant pursuit of material improvement and product innovation, the Hermsdorf plant has produced numerous developments and additions to our core product range. In the late 1960s, Hermsdorf produced complex high technology such as X-ray tube components and anodes based on molybdenum alloys. Today, the Hermsdorf plant is our only facility that melts molybdenum on an industrial scale and produces a wide range of Mo-based components for critical downstream applications. To achieve our own sustainability goals, we have also developed a strong focus on recycling chips, scrap and used components for maximum efficiency.

The successes of our Hermsdorf facility

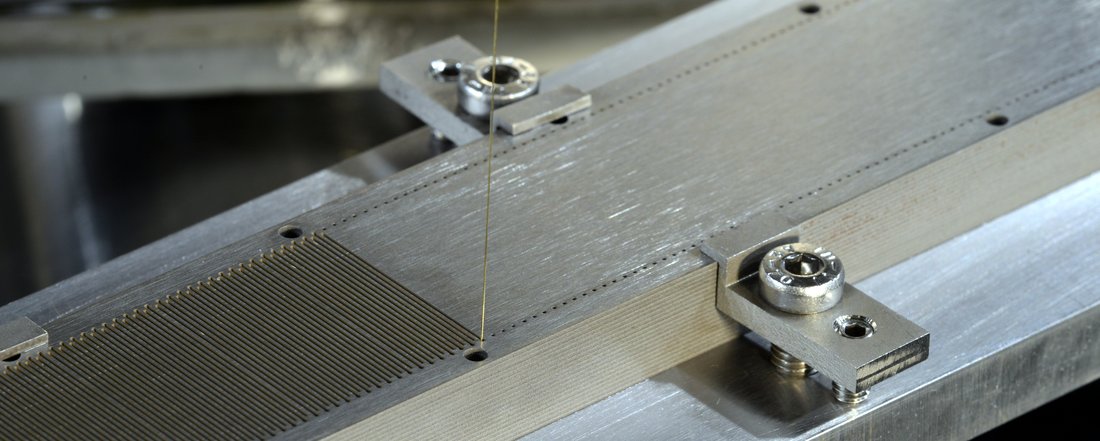

The molybdenum alloys we produce are used as cathode wafers in medical imaging equipment, as electrodes in glass melting equipment and much more. With high-precision CNC machining capabilities and unmatched materials expertise, our Hermsdorf facility is uniquely positioned to produce critical refractory metal parts with tight tolerances for demanding end-user scenarios. The Hermsdorf plant also has renowned capabilities for isostatic pressing, rolling, brazing, electrical discharge machining (EDM) and optical metrology, providing a large manufacturing footprint for fabricated components in a range of downstream markets, including heavy metal tooling and aircraft components. We are consistently proud of the achievements of our Hermsdorf team, one of the largest and most profitable refractory powder metallurgy plants in the region.

Contact

QSIL Metals Hermsdorf GmbH

Robert-Friese-Straße 4

07629 Hermsdorf

Germany

Phone: +49 36601 922101

E-mail: sales.hermsdorf(at)qsil.com